|

|

|

|

|

|

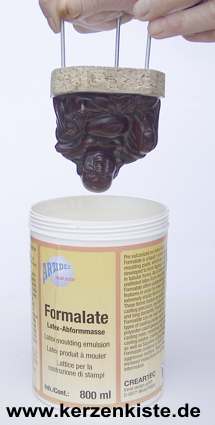

Latex emulsion

|

|

Latex is produced on the base of natural rubber. It smells of ammoniac - the preserving agent. The latex for dipping, available on www.candlecraftcenter.com,

is self vulcanizing and becomes an elastic and quite tear-resistant compound when it cools. Neither its tear resistance nor its aging resistance are as good as the ones of silicone rubber but

it’s a cheap alternative for the creation of candle moulds and, as well, for the making of plaster, polyester, ceramic compound and soap.

One doesn’t have to build the mould of latex so thick that it stands by itself.

Put it in a sand bed to improve stability.

If you use originals of glass or

metal, we’ll recommend to paint it first of all with latex koaliasator. Thus it won’t need that much time to dry.

|

|

Glue the object which you want to duplicate on a wooden plate. By now, you must have already thought about how to fill the form later on. (see below).

|

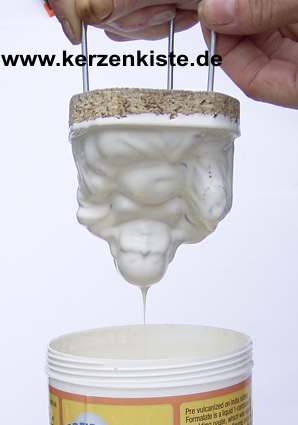

Dip it head first into latex or paint it with latex.

|

|

|

|

|

|

|

Let it dry for one hour before repeating to dip in into latex until a sufficiently thick layer forms. Heat reduces the time that needs the object to dry.

|

|

|

Deduct the solidified form. As we have already mentioned, sometimes the form is not self-supporting. In the following we will tell you two ways to fix the form in order to fill it.

1. To embed it into sand

2. To hook it in a hole which is either in a cardboard or in a wooden plate.

In each case, you have to know how you want to fill your form finally before starting the construction.

|

|

|

|

|

|

|

|

|

|

|

Fix your finished form either in a sand bed or in a frame of card or wood.

Fill it with wax, plaster, polyester, ceramic compound or

soap.

|

|

|

|

|

|